MENU

|

|

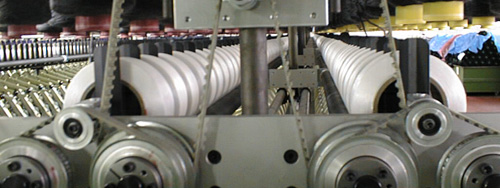

CONSTRUCTION, TRANSFORMATION AND AUTOMATION OF TEXTIL MACHINERY

|

Filcom Core:

Description

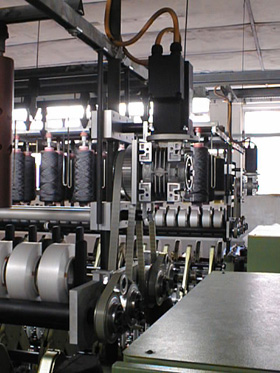

Electro-mechanic device and automatic control software for the production of RIGID CORE and ELASTIC CORE Yarns.

In the CORE yarn spinning system, a core of filament is totally covered by fibers with the objective of achieving a new functionality of the yarns.

They are two types of CORE yarns:

- RIGID CORE-Yarn (rigid filament core).

- ELASTIC CORE-Yarn (elastomer core).

Advantages of Filcom Core Equipment

Simplicity: Removal of mechanical transmission parts, simplification of the assembly and maintenance.

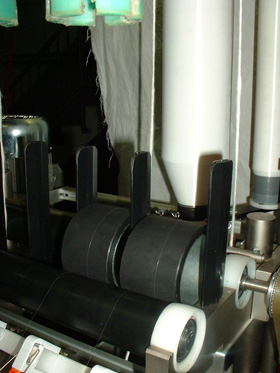

Accuracy: Provides maximum regulation and automatic on-line control of the filament tension and its feeding speed, assuring a uniform and complete recovering of the same.

Effectiveness: Use of quality materials, in order to guarantee an optimized running, free of frictions, of any type of filament.

Adaptability: To any Conventional Spinning machines. Minimum energy consumption.

Technical features

Guarantee of uniform recovering of the inserted filament: The system enables the programming and on-line control, in precise and effective way, of the following parameters:

- Feeding speed of the filament.

- Filament preliminary tension.

- Optimum filament centering in the spinning triangle: The main objective is to situate the filament, rigid or elastic, inside the yarn, in such a way that the fibers totally recover the filament. This is achieved by means of a roller-guide system, which accompanies the filament until it's centered in the spinning triangle before the twisting process.

- Controlled feeding of filament packages: The filament-feeding creel it's built with steel cylinders, which are balanced and treated with black chromium.

Quick and simple production of wide yarns range: The simplicity of the system allows the immediate change of produced yarn through the keyboard.

Filament Detector: Optionally, the unit can be equipped with an individual alarm device, for each production unit, to detect filament breakage or when filament package has finished.

Microprocessor and software composed of:

- Graphic screen of 120 x 70 mm.

- Production of compound or normal yarn count without change of the draft gear.

- One or many parameters of the of the produced yarns can be changed in the screen without stopping the machine.

- Alarms that facilitate troubleshooting.

| NET ENGINEER, WEB CREATION | LEGAL NOTICE |