MENU

|

|

CONSTRUCTION, TRANSFORMATION AND AUTOMATION OF TEXTIL MACHINERY

|

Movijet:

Description

With the MOVIJET Rope dyeing machine is improve the cost-effectiveness of processing keeping intact the quality of the fabric. The maintenance and installation are easy so the manpower requirements are reduced.

With the MOVIJET it is achieved:

- Output increase by reducing dyeing processing times.

- Best quality security and a high level of operational reliability.

- Diminution of the production costs by the consume reduction of dyeing auxiliary products, water, steam and energy.

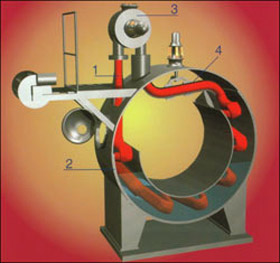

1 Fabric

2 Store chamber

3 Drive reel

4 Plaiting system

2 Store chamber

3 Drive reel

4 Plaiting system

Characteristics

- The machine body is in two versions: Cylindrical Shape and Circular Crown Shape. Thanks to this feature it is really gotten liquor ratios as low as 1:3 at 1:5.

- Designed as Jet-Overflow dyeing machine, suitable for the treatment in humid of all type of knitted fabrics, terry cloths (towels) and delicate woven fabrics.

- Fabric transport system: Special design of the fabric drag reel and it is prepared to works up to 500 m/min.

- The regulating Jet-Overflow conduce the fabric by flotation in order to avoid pilling formation and stitch deformation in the knitted fabrics.

- Connected to the Jet-Overflow is the movable plaiting tube. Its function is to arrange and store the greatest possible quantity of fabric, achieving a liquor ratio reduction and, in the same way, avoid material tangle occurrence.

- The fabric tilts inside the storage basket without any tension. Crush marks are avoided because of the curvature and cross-section of the store chamber.

- The dye liquor circulation is carrying out by a high capacity centrifugal pump; it impels the liquor to a filter and them to a heat exchanger (up to 6ÂşC per minute).

- Two additions tanks, one for colorants and another for auxiliary products. Equipped with dosage litre to litre, agitator, probes, douches, filter, valves and introduction pump.

- Substantial MOVIJET capacities: Available in capacities of 10, 25, 50, 150, 300, 450 and 600 Kilos. It is feasible to join machines of the same capacity, so it is possible to dye up to 1.200 Kg.

Cylindrical Version, VN-2/150 Model, High Temperature, 300 Kg

Cylindrical Version, VN-1/10 Model, High Temperature, 10 Kg

| NET ENGINEER, WEB CREATION | LEGAL NOTICE |